Tire Manufacturing

Pull the plug on Costly Leaks

Leaks of all types are common in tire manufacturing. Swagelok associates can help identify and stop them, keeping your operations safe, productive, and profitable.

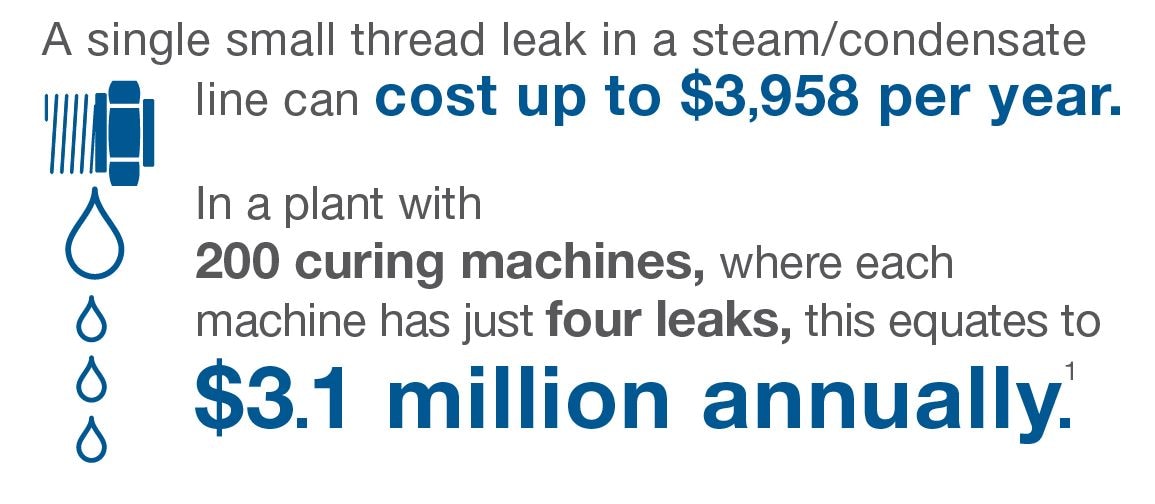

Steam and Condensate Leakage

Problem: The leading cause of leaks in a steam and condensate system is the use of threaded pipe connections; however, welded connections also have shortcomings.

Solution: Swagelok tube fittings provide many advantages over threaded pipe/welded connections due to robust construction, extensive testing, and easy workability.

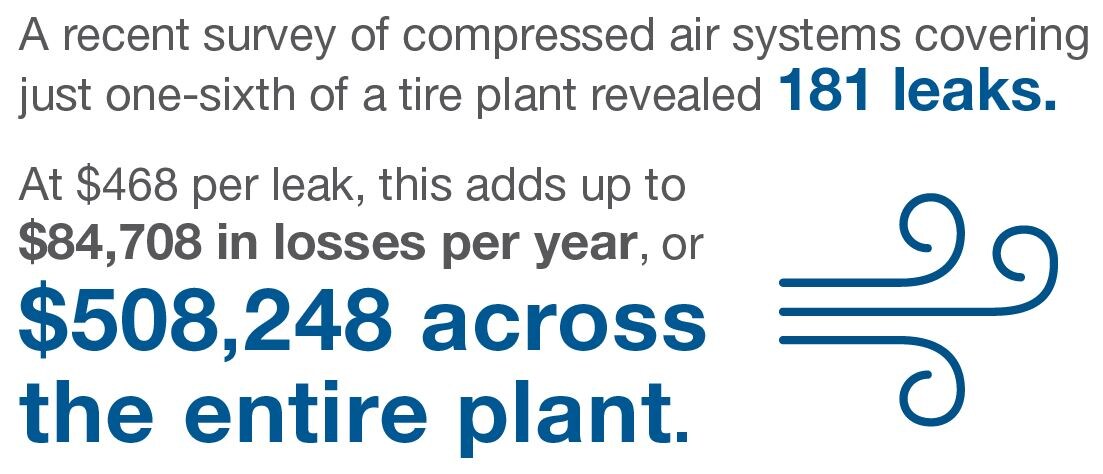

Compressed Air Leaks

Problem: Compressed air systems are found in nearly every industrial facility, and nearly all have leaks. If you notice that compressors are running longer without any other changes being made to the system, it's a good bet the system has developed leaks.

Solution: A leak survey from Swagelok can help you reconsider what compressed air leakage is doing to your bottom line. It’s often more harmful than you think—leakage can eat away 20 to 30% of a typical compressor's output efficiency.

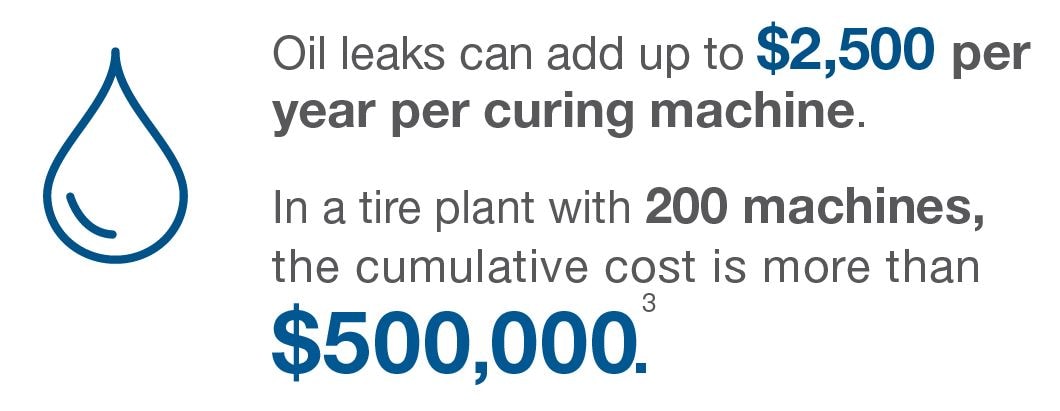

Hydraulic Oil Leaks

Problem: The costs associated with hydraulic oil leaks include:

• Makeup Fluid

• Cleanup

• Disposal

• Contaminant Ingress

• Safety

Solution: Swagelok products are rigorously tested to stringent standards for quality and performance, meaning you can be confident these components deliver high value and low total cost of ownership.

Paths to Plant Optimization

Stronger components are just part of a healthy fluid system. As a complete solutions provider, Swagelok is engineered to take the pressure off of you.

Leverage Our Fabrication Services

Need to bring an idea to life? Our Fabrication Services can follow your design, or, with a Swagelok tech center, can create an entirely new design, all backed by our Limited Lifetime Warranty.

Avoid Costly Waste and Rework

We'll detail the subsystem specifications, budget, performance needs, and timetable, providing a proposal and 3D CAD model. Then we'll optimize it, assemble it, test it, certify it, and warranty it—delivering exactly what you need, with no prototyping, time crunch, or headache.

Let Our Services Come to You

Swagelok Evaluation and Advisory Services put experienced industry pros in your plant with one goal: improving the reliability and safety of the operation. From a thorough steam system audit to compressed gas leak detection to a close look at the hoses that keep things flowing smoothly, you can trust us to engineer stronger solutions every day.

Get the Training You Need

We offer among the most comprehensive steam and fluid system training available, with a special focus on keeping you alert to hidden dangers. From on-site learning to off-site classes that accommodate busy schedules, we make it easy to go through our in-depth education programs led by qualified instructors. That's why many of the world's largest industrial operators choose Swagelok to help their associates work safer.

Learn more about how we can take the pressure off of your tire manufacturing business by contacting us.