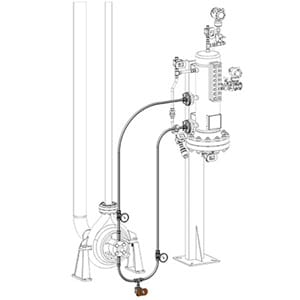

API Plan 52 Buffer Fluid Seal Pot

API Plan 52 utilizes a reservoir and circulates an unpressurized buffer fluid between the inboard and outboard seals. To provide positive circulation through the support system and into the seal, a pumping ring is employed. Frictional losses in the buffer fluid inlet and outlet lines should be minimized by selecting the proper tube size, using large radius and/or 45 degree bends, and reducing the length of tubing runs. Plan 52 is commonly used with light hydrocarbons or fluids with a high vapor pressure. The buffer fluid must be compatible with process fluid as inboard seal leakage will eventually mix with the buffer fluid.

API Plan 52 Seal Pot Assembly and API Plan 52 Kit

Assembly and kit shown with some optional components.

This plan:

- Provides additional heat removal from the inboard seal when required

- Acts as a secondary seal to prevent process fluid leakage to atmosphere

Plan 52 is available as a seal pot assembly. The associated field installation kit for use in connecting the seal pot assembly to your system is also available. Assembly components may include:

- Swagelok tube fittings

- 63 series ball valves

- CH series check valve

- V series 2-valve manifold

- QTM series quick-connects

- Bimetal thermometer

- TTW series thermowell tee

- PGI series gauges

- Swagelok pipe fittings

- Pressure transmitter

- Level transmitter

- Level switch

- Seal pot

See page 31 of the Mechanical Seal Support Systems Application Guide for additional details and ordering information. Contact your authorized Swagelok sales and service center for information on optional components.