API Plan 53C Barrier Fluid Pressurized by Piston Accumulator

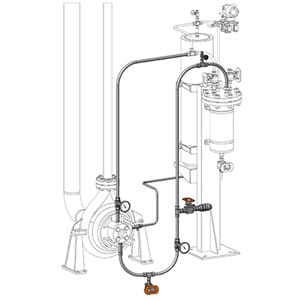

API Plan 53C circulates a pressurized barrier fluid between the inboard and outboard seals. The source of pressurization is a piston accumulator. Plan 53C is preferred for applications where the seal chamber pressure may vary during pump operation. A sensing line is typically run from the seal chamber into the piston accumulator, allowing for a constant pressure differential to be maintained. As with Plan 53A and Plan 53B, barrier fluid must be compatible with process fluid and some level of process dilution be acceptable. In order to provide positive circulation through the support system and into the seal, a pumping ring is employed. Heat removal is achieved by using a heat exchanger.

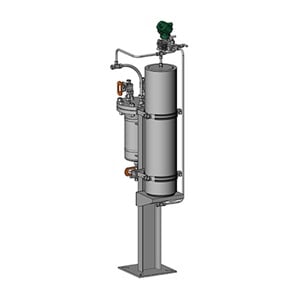

API Plan 53C Assembly and API Plan 53C Kit

Assembly and kit shown with some optional components.

This plan:

- Provides additional heat removal from inboard seal when required

- Is used when the seal chamber pressure can vary during pump operation

- Is used when process leakage to atmosphere cannot occur

Plan 53C is available as an assembly. The associated field installation kit for use in connecting the assembly to your system is also available. Assembly contents may include:

- Swagelok tube fittings

- 63 series ball valves

- 1 series needle valve

- V series 2-valve manifold

- QTM series quick-connects

- TTW series thermowell tee

- Swagelok pipe fittings

- Differential pressure transmitter

- Level transmitter

- Level switches

- Level indicator

- Piston accumulator

See page 43 of the Mechanical Seal Support Systems Application Guide for additional details and ordering information. Contact your authorized Swagelok sales and service center for information on optional components.